The importance of water in the cooling tower industry – Water (part 9)

Some of this data or design values are questionable, such as the temperature of air at wet-bulb temperature, that seems to shift every year for speculation reasons.

To measure the efficiency of each tower, hence, there is a need to know the exact design data and the theory that allows to design the tower, knowing the values detected by lab effective testing.

All this will be treated in another chapter with interesting considerations.

We shall use the method that will allow, at least, to compare the efficiency of the tower at the any given time with the efficiency of the tower at the time it was installed: in other words, the degradation of efficiency (if it exists).

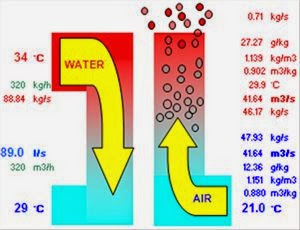

The main element for cooling water is air. The amount of air is essential for the amount of heat to dissipate, temperature, etc.

The amount of air measurement is synonymous of tower efficiency.

The degradation over time can decrease the amount of air in the tower because there are occlusions within the filling material that block the passage of air. Occlusions may originate from collapsed material, limestone, dust, algae, etc.

The masses of water and air inside the tower are huge. The water weight is about 15,000 to 30,000 kg/m2 of the tower. Thus, the water will always fall via preferential routes: holes or by laminating on the tower walls. The amount of air passing through the tower is of vital importance.

The speed in m/s and is measured with an anemometer (a very simple tool with fan). This tool is used to measure the wind speed, etc. Hence, the speed through the cross section (m2 top view) of the tower MUST be between 2.5 and 4 m/s.