The system that allows used water that was heated during the cooling of a technological system to be cooled, thus making it again, and continuously, available to give continuity to the cooling cycles, is called “evaporative cooling tower”.

Liquid refrigerant cooling is obtained through part evaporation of the same because of the simultaneous presence of heat transfer and matter transport phenomena, whose effects are increased with forced ventilation.

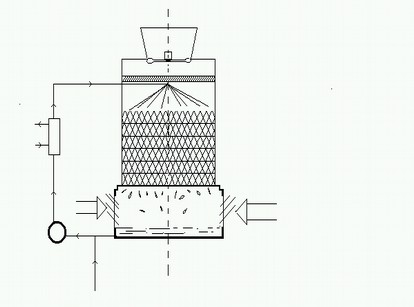

The towers are composed of an enclosure made of various kinds of shapes and materials, even if the most prevalent geometry is that of rectangular parallelepiped. Inside there is a motor fan that activates air circulation that is counter-flow with respect to the water, that falls from the top of the tower; once cooled, it’s collected in a tank and put at the base of the structure, and then put back in the refrigeration cycle.

Diagram of a counter-flow cooling tower

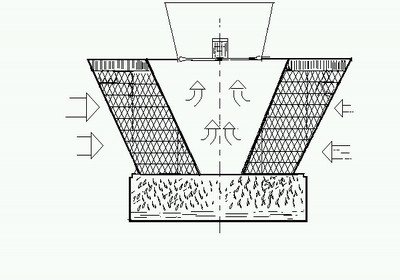

Another tower configuration is that of ‘cross-flow’. This is where the descending falling water gets hit by a stream of air, crossing it transversely horizontally.

Diagram of a cross-flow cooling tower

All the towers, except those with natural ventilation, are equipped with one or more fans, which can be both axial (also called helical) and radial (centrifugal).

The fans can be placed either at the tower air inlet (forced fan) or at the outlet (induced fan), but the centrifugal fans are just as pressing (forced).

The efficiency of the evaporative cooling system is directly proportional to the surface and the time for which the two moving fluids come in contact with each other; to further increase this feature, different types of “fill material” are used with the specific aim to increase the contact surface and, hence, the heat exchange between the two fluids by diverting, breaking and maintain, as much as possible, in contact with each other.

Inside the cooling tower, thanks to the humidification phenomenon, heat and mass transfer take place simultaneously, i.e. the evaporation of a liquid substance into a gas.

The transport of mass consists in transferring a fluid solution component from a region that has a higher concentration to a lower one; in our case, this takes place between two different phases and, simultaneously, with heat transfer .